Big Bag, Flexible Intermediate Bulk Containers (FIBCs), or Bulk Bags, were introduced to world usage over thirty years ago and since that time their use has grown rapidly as more industries have realized the cost saving potential in utilizing FIBCs in their handling and storing systems. Big Bags are ideal for those occasions when conventional bulk transportation or small-scale packagings are impractical solutions.

FIBCs are available in a variety of types, shapes and sizes and we can customize bags to suit your specific requirements with the broad options of combinations available. We stock a comprehensive range of Single Trip bulk bags with Safety Working Loads from 500kg to 2000kg and a variety of top and bottom configurations (filling and discharge). Multiple Trip bulk bags with Safe Working Loads up to 2000kg are also available in various options.

As an experienced and conventional manufacturer, our Big Bags (FIBCs) comply with world standards and are produced according to ISO 9001 and ISO 22000, and provide our business partners the confidence of only buying a quality product.

Types & Uses Of

Big Bags / Fibcs

U-PANEL BAGS

Two piece, U-Panel construction that has two seams sewn along the two opposite sides to create two panels, creating a “U” Panel shape. Accepted as the industry standard around the world, the U-Panel FIBC is the most popular FIBC shape. This construction gives the bag a large lifting capacity.

FOUR-PANEL BAGS

It is the original polypropylene design, Four-Panel Bulk Bags (FIBCs) have seams along four separate pieces of fabric that are sewn together to construct the body of the bag as well as having the top and bottom panels sewn in. Four-Panel bags tend to hold their shape better than other types of bags and are better suited for stacking.

CIRCULAR WOVEN BAGS

A Circular or Tubular bag is woven into a cylinder or tube and cut to the correct size. The most common construction type is a circular fabric on the body with a sewn square base. As there are no seams in this construction, this creates for a more aesthetically pleasing bag, and with only a top and bottom panel sewn into the bag, they are ideal for ne and hydroscopic materials. The tubular body design is also ideal as a liner-less option for ne materials and is recognized for its ease of lifting and manipulating with a forklift.

CONICAL BAGS

The Conical Bag is designed speci cally to assist in the complete discharge of contents, which are slightly sticky, like brown sugar and premix our products. The conical shape at the bottom of the bag ensures that the bulk bag can be discharged quickly and easily.

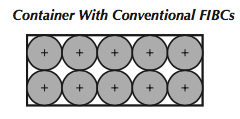

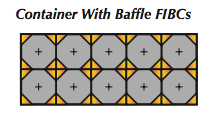

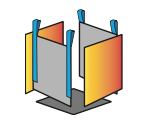

FORM-STABLE or BAFFLE BAGS

This special Baf e construction offers maximum stability to the bag. There are 4 baf es sewn to the main fabric at each corner to prevent bulging of bag when lled, allowing for a more effective use of the bag’s storage capacity. Four rigid cross corner loops allow the forklift operator to pick up bags without the requirement of additional staff. The Baf e Bag is ideal for light-density products and can be more economical as it increases payload - the larger panel width allows corners to be lled with 25%-30% more product. Another advantage is the increased stackability and with all sewn edges turned to the outside, it reduces potential of contamination.