Types & Uses

Of Antistatic & Conductive FIBCs

Type A Bulk Bags are made from standard polypropylene material which is a non-treated insulating fabric. They have no special electrostatic safety features. Static electricity is generated as products move over the inside surface of the Bulk Bag when they are being lled or discharged. As there is no static protection provided by Type A Bulk Bags, these are not to be used for combustible materials or utilised in ammable or combustible environments.

No requirements are speci ed for Type A FIBCs as they are not intended for use in potentially explosive atmospheres.

- No static protection,

- Used safely to transport non- ammable products,

- There are to be no ammable solvents or gases present around the bag,

- DO NOT USE to transport ammable products.

Type B Bulk Bags are very similar to the Type A bags as they are made from the standard polypropylene material, they too do not have the ability to dissipate static electricity ef ciently. The difference is that

the material used is an insulating fabric but this has a low breakdown voltage (less than 6KV) to prevent propagating brush discharges (PBD) which are highly energetic and dangerous. Type B bags can prevent PBD, however normal brush charges can still occur so these bags cannot be considered to be antistatic in any way. Type B bags may be used in the presence of the combustible dusts with MIE of greater than 3mj but in the absence of ammable vapours of gases.

- Used to safely transport dry, ammable powders,

- There are to be no ammable solvents or gases present around the bag,

- DO NOT USE to transport ammable products.

Type C Bulk Bags known within the industry as conductive or groundable Bulk Bags or conductive FIBCs. Constructed from non conductive polypropylene material interwoven with conductive yarns that form a grid pattern, these are designed to control electrostatic charges by grounding. The bag MUST be electrically grounded during lling and emptying - this is essential to the safe use and performance of a Type C bag.

- Used safely to transport ammable powders,

- Used safely when ammable solvents or gases are present around the bag,

- DO NOT USE when ground connection is not present or has become damaged.

Type D Bulk Bags are also called antistatic Bulks Bags. A type D bag is constructed from antistatic fabric which has antistatic or static dissipative properties to safely prevent the occurrence of incendiary sparks, brush discharges and propagating brush discharges and does not require grounding.

- Used safely to transport ammable powders,

- Used safely when ammable solvents or gases are present around the bag,

- DO NOT USE when the surface is contaminated or coated with conductive material such as water or grease.

Some Facts About Conductive Bags

The FIBCs known as “Type C Bags” have interwoven conductive threads which are all reliably interconnected and MUST BE GROUNDED. Dangerous static charge is safely dissipated to ground. Type C bags do not cause any discharges. But the most important condition is a reliable connection to ground during lling and emptying operations. To prevent grounding errors, Type C bags are additionally equipped with conductive loops in order to achieve contact to the hoist system, providing it has a path to ground. If this FIBC remains ungrounded and grounded objects are approaching, spark discharges will occur which can ignite gases, vapours and dusts.

Causes of electrostatic charging

Electrostatic charging is generated when separating a non-conductive material from another one (either non- conductive or conductive) which were in close contact with one another. When lling or discharging an FIBC, an electrostatic charge accumulates to the top of the lled material and also on the inner walls of the FIBC. These charges are built up by virtue of the resistance of the materials.

The amount of charge of a product depends on the:

- Electrical resistance of materials,

- Triboelectric properties of both materials,

- Separation speed,

- Electrical properties of product feeding systems.

Causes of electrostatic charging

Electrostatic charges are not dangerous by themselves but they may be dangerous when there is a risk of gas discharge. Different types of gas discharges are as follows:

Brush discharges: In general they are capable of igniting gases and vapours but not dusts,

Corona discharges: In general they are not capable of igniting combustible atmospheres,

Spark discharges: In general they are capable of igniting gases and vapours but not dusts,

Propagating brush discharges: They are so strong that they are capable of igniting not only gases and vapours but also dusts could be ignited.

During the lling process the strongest electrostatic charge occurrence is to be expected. Transporting itself does not increase static electricity.

During the emptying process, static charging must again be taken into account.

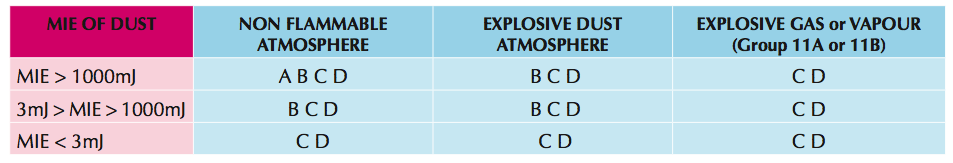

The table below will help you to identify the style of bag required depending on the sensitivity to ignition of the products being packaged and the surrounding atmospheric conditions. The sensitivity to ignition of the product being packaged is de ned by its minimum ignition energy properties, or MIE. The surroundings are classi ed in increasing sensitivity to ignition by electrostatic discharges as non- ammable, explosive dust atmosphere and explosive gas or vapours.

Hazard Zone Where Type A, Type B, Type C and Type D Bulk Bags Can Be Used